Particle Testing of SSD

Industry Pain Points:

① Different wafers and packaging factories may result in uneven quality after packaging - there may be phenomena such as open and short circuits;

② Due to different sources of Die, mixing may occur during the packaging process - it is necessary to use the Read ID method for inspection;

③ Multi die packaging, the quality of each die is difficult to distinguish - it is necessary to select and identify multiple dies;

④ Too many bad blocks in Flash result in insufficient SSD capacity - a capacity scan of Flash is required.

Previous Solutions in the Industry:

Use the finished board from the main controller to perform read ID on the chip.

Disadvantages:

① Not convenient for personalized modification;

② Frequent replacement of multiple main control boards;

③ If there are short circuits or other issues with the packaged chip, it can cause damage to the test board due to short circuits.

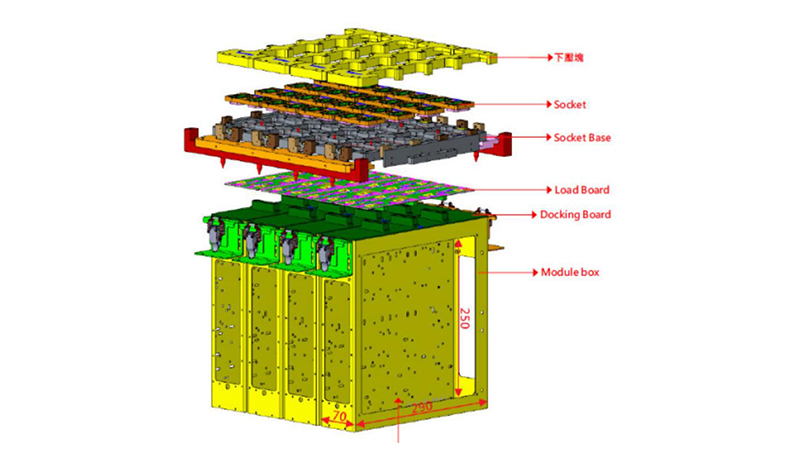

YongMing Solution:

Yongming's self-developed test board achieves the following functions:

① OS testing, first screen for open and short circuits;

② Support multi die full capacity scanning;

③ Supports Read IDs for multiple dies.

Unique advantages:

① Compatible with different wiring methods, no need for engineers to configure separately, reducing operational difficulty and workload;

② No master control restrictions, compatible with different types of flash;

③ Can achieve a maximum detection speed of 3s/pcs.

OTHER SOLUTIONS